Once the preliminary treatment of the stainless steel is completed, including the removal of the mill scale, bumps and imperfections and the stainless steel has been sanded to grit 600, one can start thinking of polishing. From 8mm, hot-rolled material is unavoidable. Our bars such as the no scratch pink can also be used to polishing plastics, woods and other composite materials. We manufacture several different color compounds that are fantastic for polishing metals such as aluminum, copper, brass, stainless steel and steel. Ideally, one would choose for the cold-rolled 2B finish, but this comes with restrictions concerning thickness. METAL POLISHING COMPOUND BARS FOR BUFFING WHEELS. This also depends on the quality of the material, but generally speaking, the grit paper can start at 240. For cold-rolled 2B finish, it takes less time to reach a polished finish on the stainless steel. With a criss-cross motion of the grinder, the previous grit paper is smoothed out. This has to be done gradually all the way up to 600 grit. Unfortunately, after removing the mill scale, you cannot go straight to a fine grit. The goal is to get the opposite, in order to polish the stainless steel. After this, the stainless steel is far from ready to be polished, because the surface is very rough and has a high surface roughness value. It is important to use a coarse grit such as 60 or 80. It is found everywhere, from the springs in tanks to the fuel lines carrying vehicle exhausts.The hot-rolled 1D material has a tough oxide layer, otherwise called the mill scale, that needs to be removed first.

Since WW2, stainless steel has also played a key role in the defense sector. A good quality piece of stainless steel serves as a buffer against the damaging effects of wind and water, maintaining safety and stability. When it comes to infrastructure, the corrosion resistance of stainless steel helps extend the lifespan of structural and architectural projects.

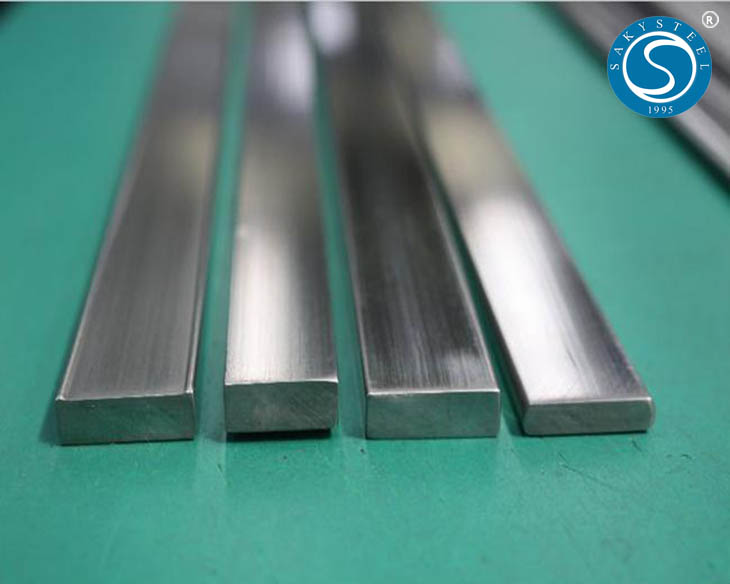

In the medical industry, stainless steel is found in nearly all the equipment that doctors use in their work as well as the many of the small, intricate parts of hospital machinery (such as the EKG or ECG) for monitoring patients. These applications can include food handling/processing (i.e., kitchen sinks, cutlery), medical instruments (i.e., thermostats), hardware, appliances, and structural/architectural uses (i.e., bridges, airport roofs). Material :SS304, SS316 Finish Available: Satin, mirror polish Complete With Square Spindle Bar & Fixings Sold & Supplied:In Pairs Neutral packing: inner. Unlike ordinary steel, stainless isn’t prone to corrosion, rusting or staining from water exposure – giving it many versatile applications. The most common of these steps include hot rolling, cold rolling, annealing, descaling/ pickling, cutting and finishing. You can have everything from stainless steel tubing and stainless steel pipes to a stainless steel bar and stainless steel sheet.ĭepending on which grade or shape is being produced, a piece of stainless steel may go through some processing steps multiple times before reaching the desired appearance or characteristics. Stainless steel also comes in many different shapes and dimensions. There are more than 100 grades of stainless steel – most are classified into five groups in the family of stainless steels: The exact composition is strictly measured and assessed throughout the alloying process to ensure the steel demonstrates the required qualities. Other elements can be added to increase corrosion resistance (nickel) and formability (molybdenum). Stainless Steel Round Bar, Stainless Steel Rod Manufacturer, Customer Buy Stainless Steel Threaded Bar from SS Round Bar suppliers in Singapore, Canada. This type of steel also contains varied amounts of other elements such as carbon, silicon and manganese. However, common applications of this stainless steel surface finish involve non-decorative purposes. 1D stainless steel is sometimes used as the starting point for polished finishes. Once stainless steel is put into service, it does not need to be treated, coated or painted.īesides resistance to corrosion, stainless steel is known for its: The resulting surface is slightly coarse with very low reflectivity and a typical average roughness (Ra) between 47 micrometers. This layer prevents corrosion from occurring on the steel surface the greater the amount of chromium in the steel, the greater the corrosion resistance. The chromium content produces a thin chromium oxide film on the steel’s surface called a passivation layer. Stainless steel is an iron alloy that has a minimum chromium content of 10.5%.

0 kommentar(er)

0 kommentar(er)